1. Introduction to Paper Cup Production

Paper cup Production is a rapidly growing industry that meets the increasing demand for disposable and eco-friendly products. With the rise of on-the-go beverages and heightened environmental awareness, the need for paper cups has surged. This article explores the intricate process of paper cup manufacturing, the equipment involved, and the industry’s growth potential.

2. History and Evolution of Paper Cups

The history of paper cup manufacturing dates back to the early 20th century, when concerns about hygiene and disease transmission led to the development of disposable cups. Initially, paper cups were simple and uncoated, but over time, they evolved to include coatings for durability and insulation. The industry’s evolution has been marked by technological advancements and a growing focus on sustainability.

3. Types of Paper Cups

Paper cup manufacturing encompasses various types of paper cups, each production designed for specific uses. The most common types include:

- Hot Beverage Cups: These are typically insulated with a layer of polyethylene to retain heat.

- Cold Beverage Cups: Often coated to prevent condensation and leakage.

- Vending Machine Cups: Designed to be used in vending machines, often made with a specific size and coating.

- Custom Printed Cups: These are tailored for branding purposes and can feature company logos and designs.

Each type of paper cup requires a specific manufacturing process and materials to ensure it meets the desired functionality.

4. Raw Materials Used in Paper Cup Manufacturing

The primary raw material in paper cup manufacturing is paperboard, a type of thick paper made from wood pulp. The paperboard must be of high quality to withstand the rigors of use. Other essential materials include:

- Polyethylene (PE): A plastic coating that makes the paper waterproof.

- Inks: Used for printing designs and logos on the cups.

- Glue: For sealing the edges of the paper cups.

- Additives: To enhance the paper’s strength and durability.

The choice of raw materials significantly impacts the quality and environmental footprint of the final product.

5. The Paper Cup Manufacturing Process

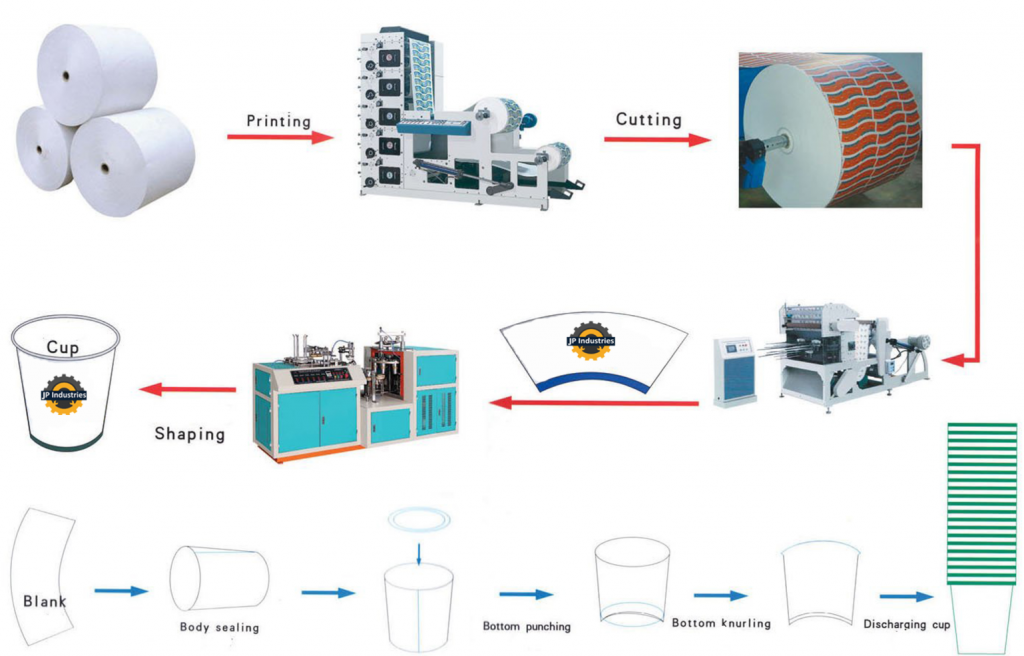

The paper cup manufacturing process is a multi-step procedure that transforms raw paperboard into finished cups. Here’s an overview of the main steps:

a. Paper Cutting

The process begins with cutting large rolls of paperboard into smaller pieces that will form the body of the cup.

b. Printing

The paper is then printed with the desired designs and logos. This step is crucial for branding purposes.

c. Cup Forming

Next, the printed paper is shaped into a cylindrical form, and the edges are sealed with glue.

d. Bottom Sealing

The bottom of the cup is added and sealed to ensure it’s watertight.

e. Rim Curling

The rim of the cup is curled to provide a smooth edge for drinking.

f. Quality Inspection

Finally, the cups undergo a thorough inspection to check for defects or leaks.

This systematic process is what makes paper cup manufacturing both efficient and reliable.

6. Machinery and Equipment for Paper Cup Manufacturing

The success of paper cup manufacturing hinges on the machinery and equipment used. Modern machines are designed for high-speed production, precision, and minimal waste. Key machines include:

- Paper Cup Forming Machines: These are the primary machines that shape and assemble the cups.

- Printing Machines: For applying designs and branding.

- Die Cutting Machines: To cut the paper into specific shapes.

- Sealing Machines: For sealing the edges and bottom of the cups.

- Inspection Systems: To ensure product quality.

Investing in high-quality machinery is crucial for any paper cup manufacturing business aiming for large-scale production.

7. Environmental Impact and Sustainability in Paper Cup Manufacturing

As the world shifts towards sustainability, paper cup manufacturing faces scrutiny for its environmental impact. Traditional paper cups, often lined with plastic, pose recycling challenges. However, the industry is evolving with innovations such as:

- Biodegradable Coatings: Replacing plastic with plant-based coatings that are easier to recycle.

- Recycled Paperboard: Using post-consumer waste to produce paper cups.

- Energy-Efficient Machinery: Reducing energy consumption during manufacturing.

Sustainability in paper cup manufacturing not only helps protect the environment but also meets consumer demand for eco-friendly products.

8. Market Trends and Growth Opportunities

The paper cup manufacturing industry is poised for significant growth, driven by several factors:

- Increase in On-the-Go Consumption: Busy lifestyles fuel the demand for disposable cups.

- Rising Environmental Awareness: Consumers prefer paper cups over plastic alternatives due to their biodegradability.

- Expansion of the Foodservice Industry: The growth of cafes, fast-food chains, and restaurants boosts demand.

- Innovation in Cup Design: Companies are developing new designs that offer better insulation and usability.

These paper cups trends production highlight the promising future of the paper cup manufacturing industry.

9. Challenges in Paper Cup Manufacturing

Despite its growth potential, paper cup manufacturing faces several challenges:

- Raw Material Costs: Fluctuations in the cost of paperboard and other materials can impact profitability.

- Environmental Regulations: Stricter regulations on single-use plastics and waste management require manufacturers to adapt.

- Competition: The industry is competitive, with numerous players vying for market share.

- Recycling Challenges: Ensuring that paper cups are recyclable remains a significant issue.

Addressing these challenges is essential for the long-term success of any paper cup manufacturing business.

10. Future Prospects of Paper Cup Manufacturing

The future of paper cup manufacturing looks promising, with continuous innovation and a focus on sustainability. Advances in biodegradable materials, recycling technologies, and energy-efficient production methods will shape the industry’s future. Additionally, the increasing demand for personalized and branded cups will drive further growth.

As the world continues to prioritize environmental sustainability, the paper cup manufacturing industry must adapt and evolve to meet these demands, ensuring a balance between convenience and ecological responsibility.

Conclusion

Paper cup manufacturing is an industry that combines traditional production techniques with modern innovations. From the selection of raw materials to the final inspection of the product, each step in the process is crucial to producing high-quality, eco-friendly paper cups. As demand continues to rise, manufacturers must focus on sustainability and innovation to stay competitive in this evolving market.

By understanding the history, process, challenges, and future prospects of paper cup manufacturing, businesses and consumers alike can appreciate the complexity and importance of this industry in today’s world.